Fabrication Capabilities

Turning Ideas Into Exceptional Metalwork

Harty Manufacturing delivers a wide range of metal fabrication capabilities designed to meet the needs of your most demanding projects. From working with high-quality materials to leveraging advanced tools and techniques, we provide the precision, durability, and aesthetic appeal your business depends on. Explore how our cutting-edge capabilities can bring your vision to life.

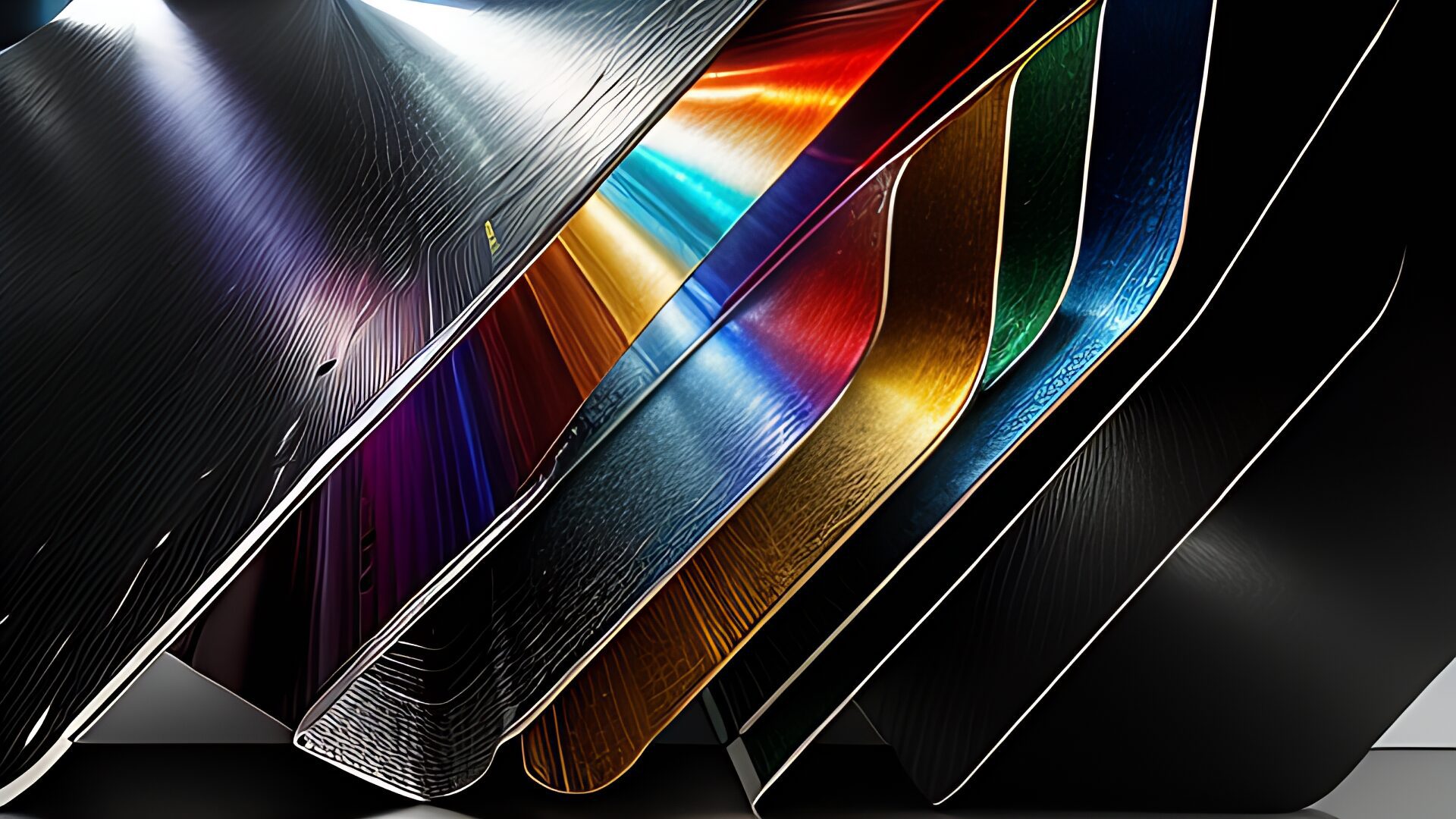

Materials: Versatility and Quality Combined

The Right Metals for Every Project

At Harty Manufacturing, we understand the importance of selecting the best materials for your unique applications. We work with a variety of metals, including steel, aluminum, and specialty alloys, to ensure your project meets its functional and aesthetic requirements. Whether you need lightweight aluminum for a sleek design or sturdy steel for heavy-duty construction, we’ve got you covered.

Choosing the right materials can be overwhelming, but we’re here to guide you through the process and make it easy.

METAL OPTIONS

- Galvanized Sheet

- Stainless Steel

- Mild Steel Sheet

- Tube, Bar, Angle, Round

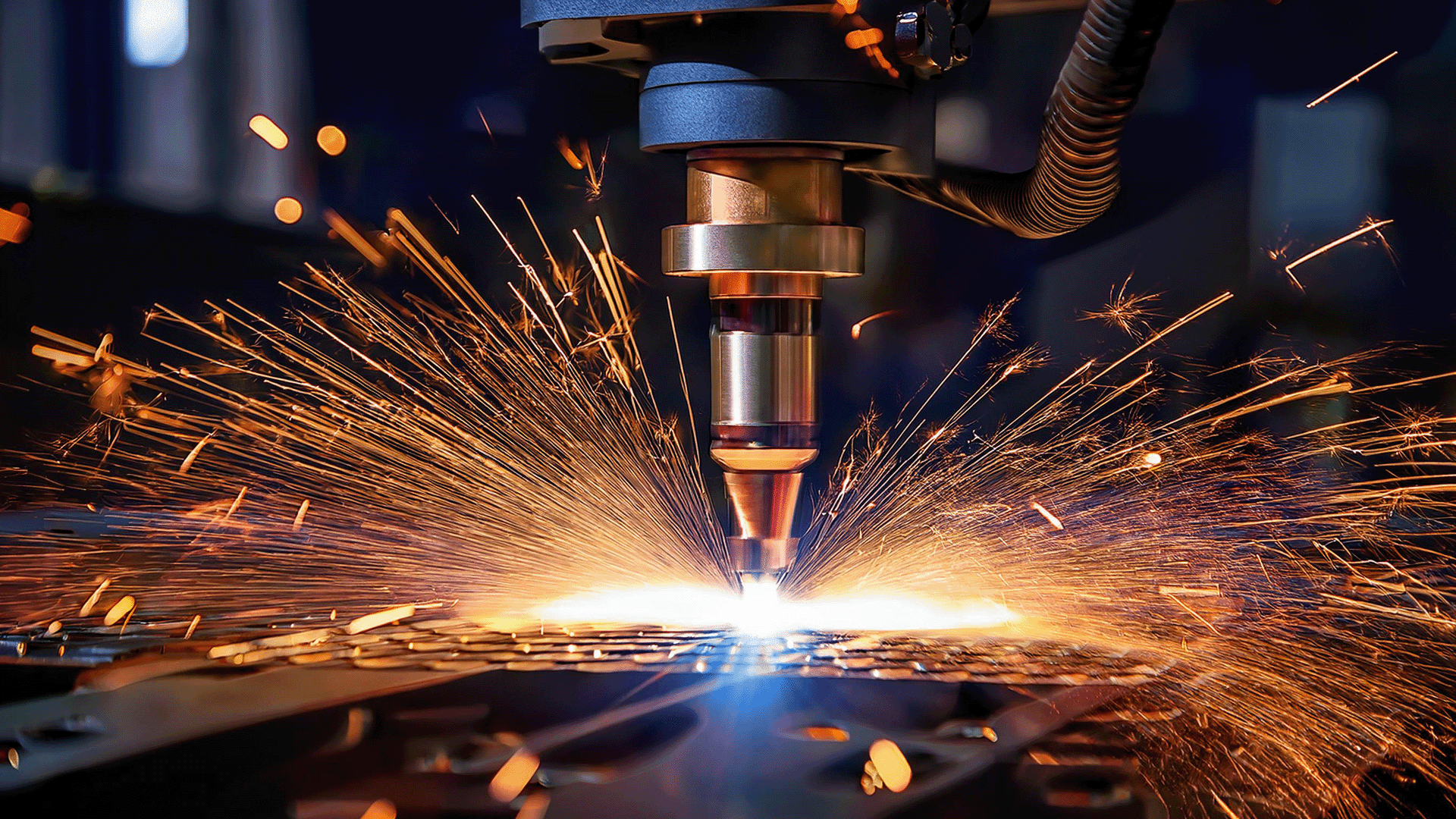

Cutting: Precision at Every Step

Advanced Cutting Techniques for Flawless Results

Our cutting capabilities ensure every component is crafted with accuracy and consistency. Using tools like our CNC plasma cutter, we create precise shapes and dimensions to match your project’s needs. From prototypes to production runs, our cutting services deliver reliable results every time.

We know precision is essential to your project’s success, and we take pride in delivering exceptional accuracy.

METAL CUTTING

- CNC Plasma Table

– 5’x10′ up to 1.5″ capacity - Metal Band Saw

Bending: Crafting Shapes with Precision

Expertise in Metal Forming

Using our advanced press brake tools, we shape metals into functional components and aesthetic designs. Whether you need angles, curves, or intricate forms, our bending services ensure each piece is fabricated to perfection.

We understand how crucial accurate bending is to the integrity of your project. That’s why we put precision first.

METAL Bending

-

60 Ton Press Brake

– multiple die angles

– 8′ Length -

Tubing bender

– dies 1″ square, 1.5″ square, 1.75 round

Metal Finishing: Enhancing Durability and Appeal

Finishing Touches That Make a Difference

Our painting and finishing services, including powder coating, ensure your components are not only functional but also visually stunning. From protective coatings to vibrant colors, we provide the final touches that set your project apart.

We know how important a perfect finish is to your project’s success. Trust us to deliver results that exceed expectations.

Solving Your Toughest Metal Fabrication Challenges

When your project requires precision metal fabrication, finding the right partner can be overwhelming. Whether it’s sourcing the right materials, ensuring exact cuts and bends, or achieving a flawless finish, the process can feel complicated and time-consuming. Mistakes or delays can cost you time and money, and finding a reliable manufacturer who understands your needs isn’t always easy.

At Harty Manufacturing, we get it. We know the frustrations of trying to bring a metal project to life while managing budgets, deadlines, and quality concerns. That’s why we make it easy. With expert craftsmanship, state-of-the-art equipment, and a commitment to your success, we handle the tough work so you don’t have to.

Let’s build something great—together.

Got Questions About Our Capabilities? We’ve Got Answers.

Choosing the right manufacturing partner means knowing they have the tools, expertise, and processes to get the job done right. At Harty Manufacturing, we’re here to make things simple. Whether you’re wondering about material options, fabrication techniques, or project timelines, our FAQ section covers the key details to help you move forward with confidence.

What types of metals do you offer?

We work with steel, aluminum, brass, and specialty alloys tailored to your project requirements.

Can you source specialty materials?

Yes, we can source specialty metals based on your unique specifications.

What thickness of Metals can you cut?

We can cut metals up to 1.5 inches thick with the CNC Plasma Cutter and other precision tools.

What file formats do you accept for cutting designs?

We accept most CAD and vector-based file formats.

What types of bends can you create?

Our 60 Ton Press Brake can create a wide range of angles and curves to suit your needs. We have multiple common dies already in the shop. We also use a Tubing bender with dies for: 1 in sq, 1.5 sq and 1.75 round.

Do you handle large-scale bending projects?

Yes, our fabrication shop is equipped to manage projects of all sizes. We have high tech tools for large project projects involving galvanized sheet metal, Stainless Steel, mild steel sheet, Tube, Bar, Angle, and Round stocks

Can you match custom colors?

Yes, we can match specific color requests for branding and design.

How long does the finishing process take?

Turnaround times depend on the project size, but we prioritize efficiency without sacrificing quality.

How It Works: A Simple 3-Step Process

Step 1: Share Your Project Requirements

Tell us about your project, and we’ll help identify the best solutions.

Step 2: We Handle the Details

From design and fabrication to production and finishing, we manage every stage with precision.

Step 3: Receive Your Completed Project

On time and to your exact specifications, your finished components are ready for use.

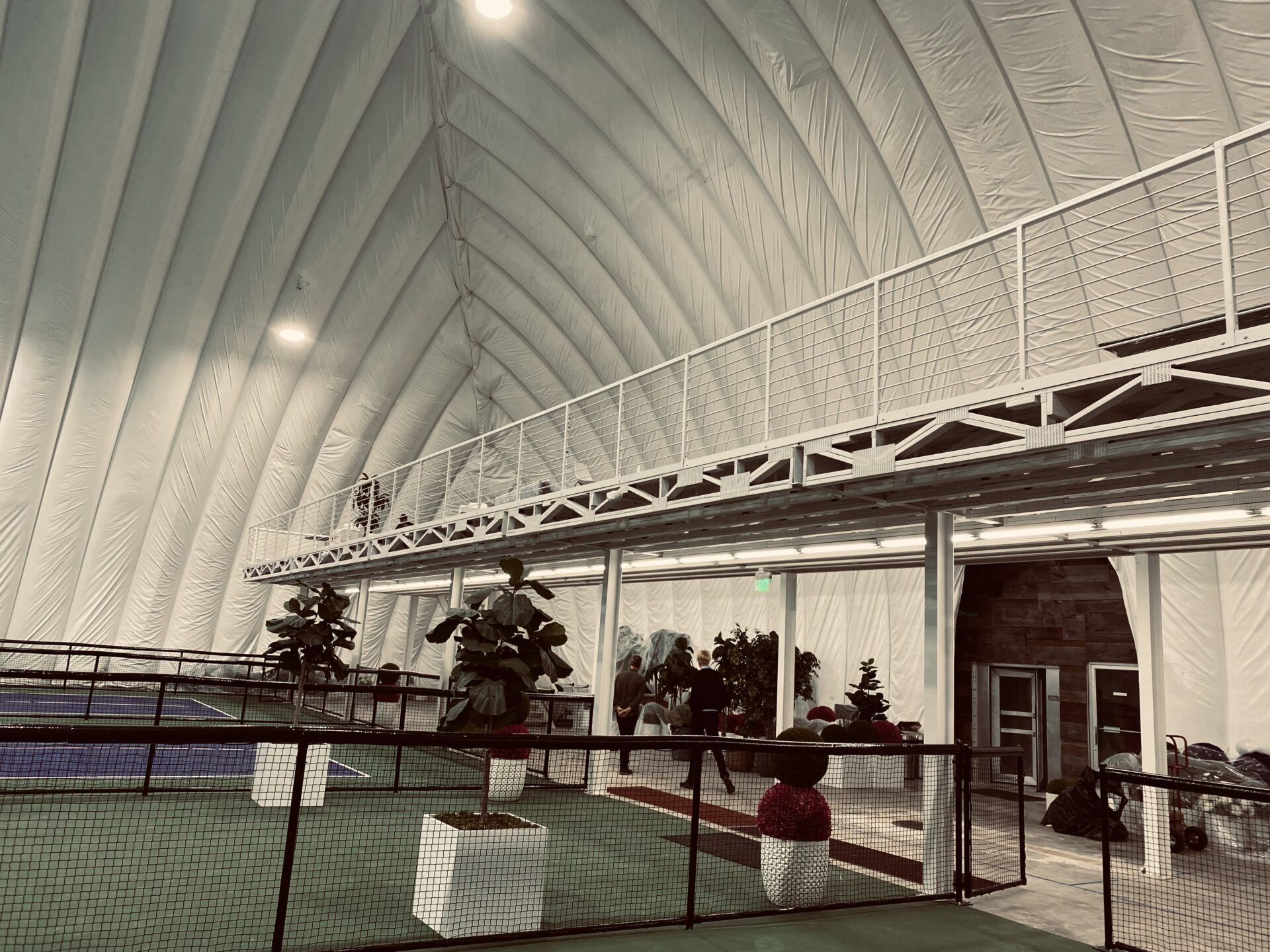

metal fabrication Solutions

Metal fabrication is at the core of what we do. From cutting and shaping to final assembly, our team produces components that are as functional as they are reliable. Here is some of our latest projects that prove our point.

Experience Metal Fabrication in a better way

Experience the Harty Manufacturing Difference